Detergent grade CMC accounts for a significant proportion of all types of CMC consumed each year. The typical recommended dosage in a standard laundry detergent formulation is between 0.5% and 3% by weight. Why it is so popular in detergent industry? Let’s discuss the properties of CMC and the main roles it plays in detergent products.

What are the core properties of detergent grade CMC?

- Water solubility: It dissolves in water to form a transparent, viscous colloidal solution. It is stable in a wide pH range (generally pH 5-10), which matches the alkaline environment of most detergents.

- Salt tolerance: It has good compatibility with most other detergent ingredients, such as sodium sulfate, without flocculation or precipitation.

- Biodegradability: It is environmentally friendly and biodegradable in nature, meeting the requirements of green detergent formulations.

- Film-forming property: It can form a thin, flexible film on the surface of objects, which helps to prevent dirt from reattaching.

What are the main functions of CMC in detergent products?

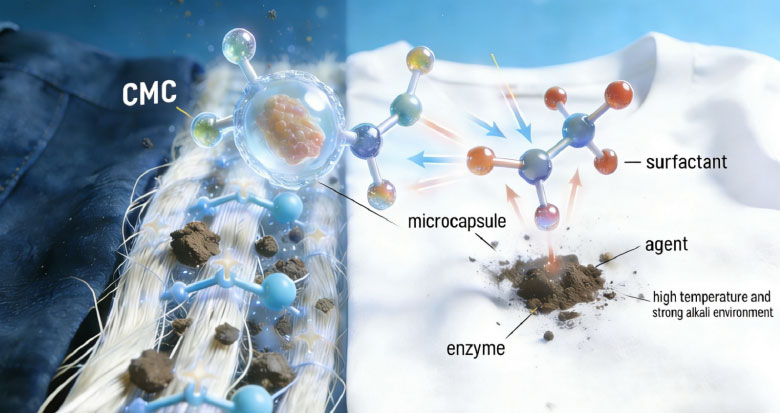

- Anti-redeposition: When washing clothes or tableware, CMC molecules can adsorb onto both the fabric and dirt particles, creating a negative charge that causes electrostatic repulsion. The dirt particles cannot reattach to the fabric or tableware surface, thus improving the washing effect and keeping the fabric bright.

- Thickening: It acts as a viscosity modifier in liquid and paste detergents to ensure a suitable consistency for proper application and preventing ingredients from separating over time. This is convenient for use, storage and transportation.

- Dispersion and Emulsification: It can disperse solid soil particles and emulsity oily dirt in the washing solution, preventing the dirt from re-depositing or settling at the bottom of the washing machine or basin.

- Stabilizer for active ingredients: It can protect the active ingredients in detergents (such as enzymes, surfactants) from being damaged by high temperature, strong alkali or other factors, and extend the shelf life of the products.

- Fabric Care: It can make fabrics feel softer after washing and help reduce skin irritation caused by other detergent components.

What are the typical specifications of detergent grade CMC?

The specifications of detergent grade CMC can vary according to different applications. Below are some common parameters.

| Parameter | Typical Range (Powder Grade) | Typical Range (Liquid Grade) | Notes |

| Purity | ≥55% | 90%-99.5% | Ensures minimal impurities that could affect performance. |

| Degree of Substitution (D.S.) | 0.5-0.7 | 0.75-0.95 | Affects solubility and hard water resistance. |

| Viscosity | 5-40 mPa·s | 300-2000+ mPa·s | Lower viscosity aids dissolution in powder form, higher viscosity for liquid formulation. |

| pH | 8.0-11.5 | 6.5-8.5 | Ensures compatibility with the alkaline environment of most detergents. |

| Moisture Content | ≤10.0% | ≤8.0% | Prevents clumping of the powder and ensures storage stability. |

If you have any demand for detergent grade CMC, please feel free to contact us. Free samples and technical support can be provided for you.

SINOCMC Team