There are two types of appearance of CMC fine powder and coarse/granular.

In practical applications, the physical form of Sodium Carboxymethyl Cellulose (CMC) fundamentally dictates its performance on the production line.

SINOCMC produce granular CMC specifically to address the long-standing “pain points” of traditional powder—namely, poor dissolution and hazardous dust.

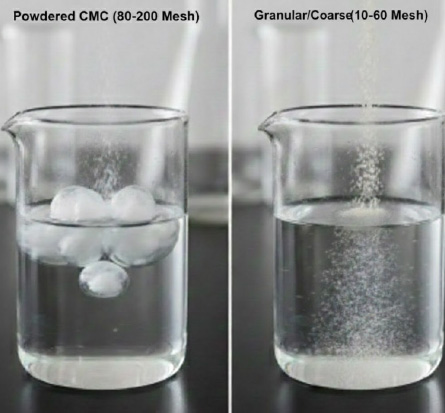

1. Physical Morphology & Sensory Comparison

Powder CMC is characterized by a fine, flour-like texture, typically ranging from 80 to 200 mesh. It has a high surface-area-to-volume ratio but is prone to clumping. Granular CMC appears as small, sand-like grains or irregular crystals, usually between 10 and 60 mesh.

2. Dispersion & The “Fish-Eye” Phenomenon

This is the most critical functional difference. When Powder CMC hits water, the outer layer hydrates instantly into a gelatinous membrane, trapping dry powder inside and creating “fish-eyes” (lumps). Granular CMC, being heavier, sinks immediately and disperses at the bottom without floating or clustering, ensuring every particle is exposed to water individually.

3. Dissolution Efficiency & Rate

While powder theoretically has more surface area, its tendency to lump makes the total dissolution time much longer, often requiring high-shear mixers. Granular CMC allows water to penetrate each grain uniformly. Consequently, its overall dissolution efficiency is 2–3 times faster than powder, resulting in a perfectly homogenous solution with less mechanical effort.

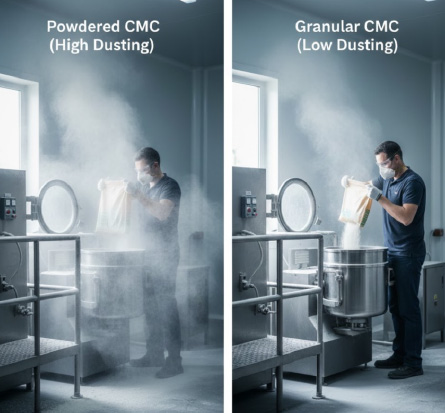

4. Operational Environment & Safety

Dust Pollution is a major drawback of powder CMC; it creates significant airborne particles during charging, leading to material waste, respiratory risks for workers, and potential dust explosion hazards. Granular CMC is virtually dust-free, ensuring a cleaner, safer workspace and higher bulk density for more efficient storage and transport.

5. Comprehensive Comparison Table

| Comprehensive Comparison Table | ||

| Feature | Powder | Coarse/granular |

| Appearance | Fine powder(80-200mesh) | 10-60Mesh |

| Dispersion Speed | Slow: Tends to float and form “fish-eye” lumps. | Fast: Sinks readily and disperses without clumping. |

| Dust Level | High: Significant dusting/loss during charging. | Ultra-Low: Virtually dust-free and clean. |

| Equipment Requirement | Requires high-shear mixers to break lumps. | Standard low-speed stirrers are sufficient. |

| Ideal Application | Dry-mix processes (e.g. detergent powder, food additive, dry-mix mortars) | Liquid-phase direct charging (e.g. mining flotation agent, oil drilling fluids) |

6. Application-Based Selection Strategy

The choice depends entirely on your process:

Choose Powder: If you are dry-blending CMC with other solids (like sugar, salt, or cement) before adding water. The other ingredients act as spacers to prevent the powder from clumping.

Choose Granular: If you are adding CMC directly into a large tank of water and lack high-shear emulsification equipment. Granular (especially instant-grade) is the premium choice for liquid-phase direct charging.

If you are willing to have a try with both types of Sodium CMC, we are glad to support you on both sample and technical support, please contact SINOCMC freely.

SINOCMC Team