Sodium Carboxymethyl Cellulose (Sodium CMC) is widely utilized as a highly effective suspending agent across various industries, particularly in food, pharmaceuticals, and industrial applications. It functions by increasing the viscosity of the liquid medium, which prevents solid particles from settling due to gravity.

Below is a detailed breakdown of how Sodium CMC performs as a suspending agent based on technical specifications and industry applications:

Functional Mechanism

Viscosity Building: High-viscosity grades, such as FH4000, which offers a viscosity of 3500–4500 cps (at 1% solution), are ideal for creating a thick enough matrix to hold particles in suspension.

Thixotropic Properties: Sodium CMC solutions often exhibit thixotropic behavior, meaning they become less viscous under shear (stirring or pouring) but regain their original thickness at rest, effectively “locking” particles in place.

Key Applications

Food and Beverage (e.g., Fruit Juices)

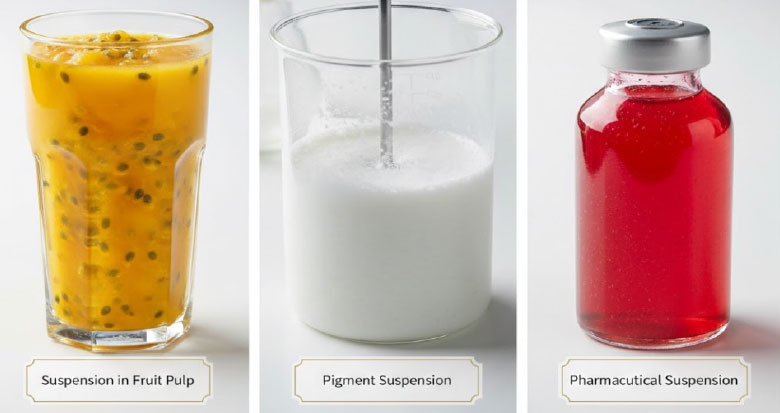

Pulp Suspension: CMC is used to keep fruit pulp and insoluble fibers evenly distributed throughout a beverage, preventing unsightly sedimentation at the bottom of the container.

Mouthfeel Improvement: In addition to suspension, it provides a smooth, “full” body to drinks without adding calories.

Paper Making (Specialty Papers):

Coating and Sizing: CMC acts as a suspending agent for pigments and fillers in paper coatings, ensuring an even distribution across the paper surface.

OGR Paper: Ultra-low viscosity CMC is specifically used in the production of Oil and Grease Resistance (OGR) paper to enhance surface quality and maintain the integrity of the treatment process.

Pharmaceuticals:

Used in oral suspensions to ensure that active medicinal ingredients remain evenly dispersed so that each dose contains the correct amount of medication.

Technical Advantages for Suspension

High Purity: For food and pharmaceutical grades, a purity level of at least 99.5% ensures that the suspending agent does not introduce unwanted contaminants.

Acid Stability: With a degree of substitution (D.S.) typically between 0.80 and 0.95, Sodium CMC remains stable and effective in the acidic environments common in fruit juices and carbonated drinks.

Environmental Benefits: In industrial settings like paper making, using CMC as a suspending agent can lead to fewer issues in waste water treatment processing (WWTP) due to its recyclability.

Selection Criteria for Suspending Agents

When selecting a Sodium CMC for suspension, the following factors are critical:

Mesh Size: Powder forms (80–200 mesh) are common, but Granular CMC (e.g., 10–60 mesh) is often preferred in large-scale production because it disperses rapidly without forming “fish-eye” lumps, ensuring a uniform suspension matrix.

Technical Specifications for Sodium CMC as suspending agent:

| Application | Recommend Grade | Viscosity | Purity |

| Juice Drinks | Food Grade | 2000-5000 | Min.99.5% |

| Paper Making | Industrial Grade | 10-200 | 70%-98% |

| Oral Suspension | Pharma Grade | 300-1500 | Min.99.6% |

If you have any idea to try our Sodium CMC used in these applications, please contact SINOCMC freely.

SINOCMC Team